- Home

-

Products

Scrap Metal Recycling Series

- Red Mini Metal Briquette Machine

- Metal Briquette Machine

- Metal Chip Briquette Production Line

- Double Output Metal Chips Briquetting Press

- Vertical Metal Briquetting Press

- Heavy Duty Metal Hydraulic Baler

- Metal Baler Machine

- Car Baler

- Vertical baler

- Horizontal baler

- Automatic hopper type metal balers

Wood processing seriesMultifunctional shredder seriesMining equipment series- Cone Crushers

- Double Rotor Crusher

- Impact Crusher

- Vibrating Screening Machine

- Tire-Mounted Mobile Cone Crushing Station

- Track - Mounted Mobile Cone Crushing Station

- Tire-Mounted Mobile Jaw Crushing Station

- Track - Mounted Mobile Jaw Crushing Station

- Tyre-Mounted Mobile Impact Crushing Station

- Track-Mounted Mobile Impact Crushing Station

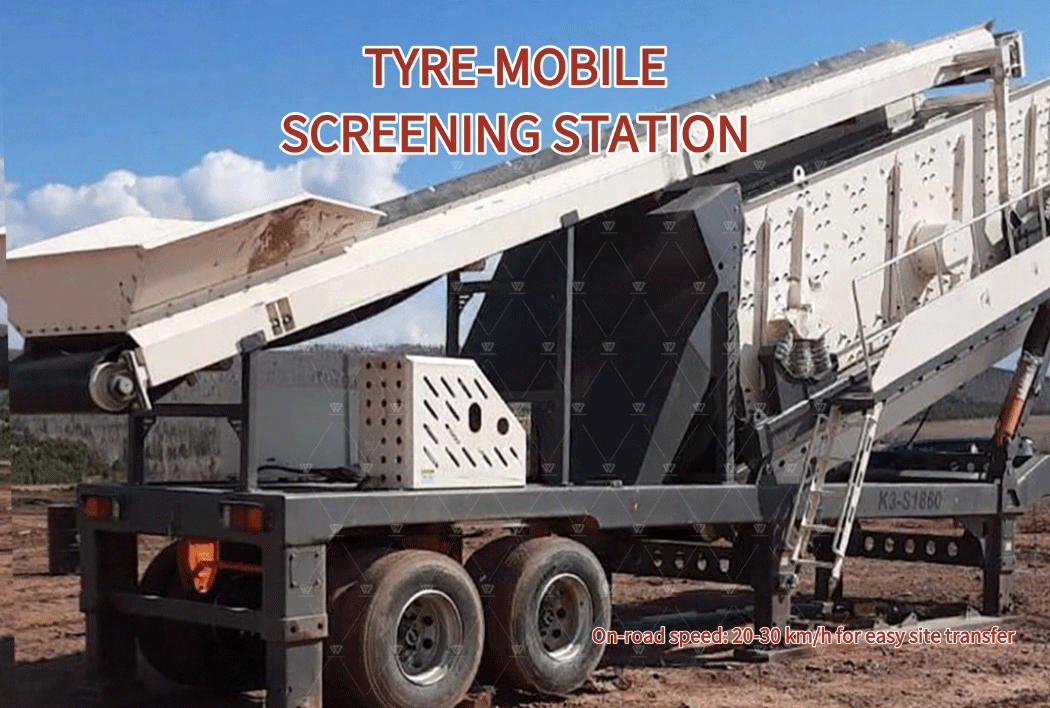

- Tyre-Mobile Screening Station

- Crawler-Type Mobile Screening Station

- Tyre-mounted Mobile Vertical Shaft Impact Crusher Station

- Hot Top sale

- Company

- Customers

- Resources

- Contact Us

Menu

Scrap Metal Recycling Series

- Red Mini Metal Briquette Machine

- Metal Briquette Machine

- Metal Chip Briquette Production Line

- Double Output Metal Chips Briquetting Press

- Vertical Metal Briquetting Press

- Heavy Duty Metal Hydraulic Baler

- Metal Baler Machine

- Car Baler

- Vertical baler

- Horizontal baler

- Automatic hopper type metal balers

Wood processing series

Multifunctional shredder series

Mining equipment series

- Cone Crushers

- Double Rotor Crusher

- Impact Crusher

- Vibrating Screening Machine

- Tire-Mounted Mobile Cone Crushing Station

- Track - Mounted Mobile Cone Crushing Station

- Tire-Mounted Mobile Jaw Crushing Station

- Track - Mounted Mobile Jaw Crushing Station

- Tyre-Mounted Mobile Impact Crushing Station

- Track-Mounted Mobile Impact Crushing Station

- Tyre-Mobile Screening Station

- Crawler-Type Mobile Screening Station

- Tyre-mounted Mobile Vertical Shaft Impact Crusher Station